When it comes to solar, fire safety is a top priority. There are many solar regulations in place to protect against the risk of fire, but constant updates are needed “to reduce hazards for firefighters while performing their duties on or in buildings with PV arrays.” – Underwriters Laboratories (UL).

Many countries have realized the importance of having safety measures in place to ensure that solar operates safely and allows firefighters and other first responders to safely access the roof area.

That’s where rapid shutdown comes into play. Let’s take a closer look at the rapid shutdown requirements and why they’re important for all solar installers and system owners to know about.

What is rapid shutdown?

Rapid shutdown is an electrical safety requirement that was originally introduced in the United States by the National Electrical Code (NEC). This requirement applies to solar PV systems and requires a way to de-energize, or reduce the voltage, of the solar modules on the roof by adding an “on or off” switch, so to speak.

Why it’s important?

Rapid shutdown provides a safe way for firefighters or solar installers to stop or reduce the voltage and current from a photovoltaic (PV) array allowing them to perform their jobs safely and efficiently avoiding electrical hazards. Turning off or reducing the voltage on your roof at the module level reduces or eliminates the firefighter’s exposure to shock from the high voltage that may be coming from the solar modules.

Do inverters already take care of this?

Inverters can shut off to prevent the energy generated by the modules from getting past the inverter. However, the solar modules will continue to generate electricity as long as the sun is shining, which creates voltage and current on the wires between the modules and inverter. As a result, most rapid shutdown codes require shutdown to occur at the module level, hence the common use of module-level power electronics (MLPE) or microinverters to meet this function. The US National Electrical Code requires that the inverter communicates with the module-level rapid shutdown device, and these components comprise a system. This “system” is what PVRSS (PV Rapid Shutdown System) refers to.

What sites must comply?

The National Electrical Code in the United States requires a rapid shutdown system for all new rooftop installations – including residential and commercial buildings. In addition, it is required if any conductors enter a building that is not specifically designed to house the PV system components. So, all new rooftop installations essentially require module-level power electronics or microinverters with the rapid shutdown function in the United States.

What makes a rapid shutdown system?

There are a few critical components involved in a rapid shutdown system:

First is a Rapid Shutdown Device (RSD). Rapid shutdown devices are a type of module-level power electronic (MLPE) or microinverter that are installed on the backs of solar modules. They are equipped with technology that can turn off and reduce voltage output throughout the solar system to adhere to PV Rapid Shutdown regulations. An example product is the Tigo TS4-A-F or 2F which is our MLPE with Rapid Shutdown compliance only, but Tigo offers multiple MLPE options with Rapid Shutdown compliance.

Another component is an initiator. A rapid shutdown initiator does exactly as the name implies. This device is typically in the form of an emergency stop (e-stop) button that is in an inverter. Typically, Rapid Shutdown can be initiated in two ways, either manually (through an e-stop button) or automatically (loss of power from the grid).

Lastly, you will need an inverter in a rapid shutdown system. An inverter is a device that converts the electricity produced by the solar modules into usable energy for your home (for more information on this process read our previous blog). Many Rapid Shutdown initiators are located inside the inverter.

These three components are referred to as Photovoltaic Rapid Shutdown Equipment (PVRSE). These are equipment used in a rapid shutdown system that reduces the voltage to a safe level. The US National Electrical Code mandates that PVRSE and PVRSS are to be UL Listed for the purposes of rapid shutdown.

Products and reference designs of Rapid shutdown

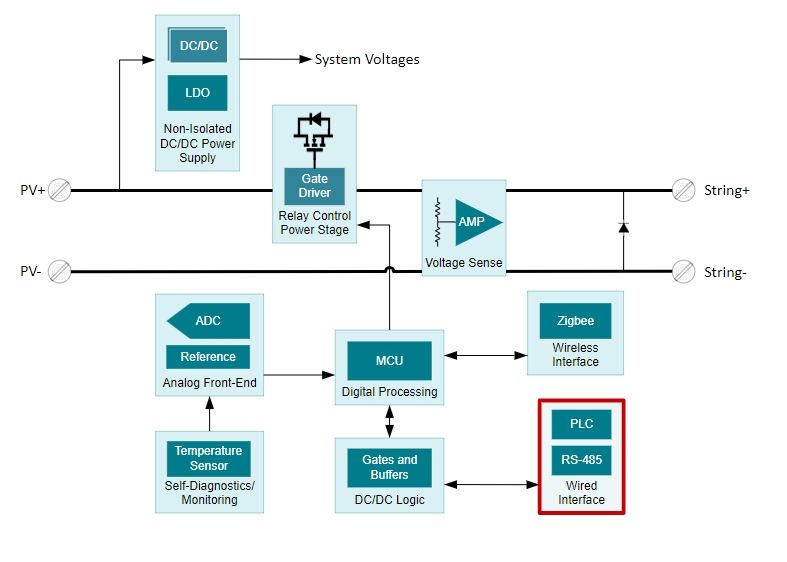

Non-Isolated DC/DC Power Supply

The internal electronics of a solar rapid shutdown system require a number of separate voltage rails. MCUs and other digital controllers will typically run at 3.3V, some digital processors operate at however voltages like 1.2V, analog circuitry will need accurate low noise reference voltages, and MOSFETs can require anywhere from 5-15V to turn on. Non-Isolated DC/DC Power Supply includes Linear & low-dropout (LDO) regulators、Buck converters (integrated switch)、Buck modules (integrated inductor), the corresponding products are LP3985、LM76005、PTH08080W

Relay control power stage

Power from the solar module needs to be able to disconnect once a rapid shutdown command is initiated. A MOSFET with dedicated driving circuitry provides a safe and reliable method of disconnecting this input from the string. Relay control power stage includes N-channel MOSFETs、Solenoid drivers, the corresponding products are CSD18512Q5B、DRV110

Voltage sense

Accurate and high speed sensory data of the input voltage enables the solar rapid shutdown to effectively track the the voltage after a shutdown command has been initiated and ensure operational safety. Voltage sense includes General-purpose op amps、Instrumentation amplifiers, the corresponding products are TLV9151、INA188

Analog front end

To ensure strict monitoring of the line voltage, the DSP requires high accuracy data from various analog sensors across the system. Dedicated analog filters and amplifiers help reduce noise and properly scale signals regardless of the ADC used. Analog front end includes Shunt voltage references、Series voltage references、Precision ADCs, the corresponding products are TL431、REF3425、ADS8578S

Self-diagnostics/monitoring

A temperature sensor is required to monitor the system power FETs as they are prone to self-heating while under load. This temperature sensor can be used as a simple thermal switch, or provide the information back to the DSP so the inverter can throttle back its power output rather than just shut off. Self-diagnostics/monitoring includes Supervisor & reset ICs、Temperature switches、Analog temperature sensors, the corresponding products are TPS3839、TMP302、TMP235

Digital processing

The main power stage in a solar rapid shutdown module is controlled by a microcontroller (MCU). Using a high-speed MCU-based solution, response time of the rapid shutdown module can be reduced significantly, quickly ensuring safe voltage levels throughout the solar system. Digital processing includes Arm Cortex-M0+ MCUs、C2000 real-time microcontrollers、MSP430 microcontrollers, the corresponding products are MSPM0G1505、TMS320F28374D、MSP430F2112

DC/DC logic

Glue logic is used to connect the power DSP to the wired communication lines in order to correctly set logic voltage levels, active high or low settings, and serve as a buffer for multiple GPIO outputs. DC/DC logic includes Noninverting buffers & drivers、AND gates、Inverting buffers & drivers, the corresponding products are SN74LVC1G125、SN74LVC2G08、SN74LVC2G04

Wireless Interface

Most modern solar rapid shutdown modules include a communication option to enable remote monitoring and control of the solar system. Wireless Interface includes Other wireless products、Low-power 2.4-GHz products, the corresponding products are CC2530-RF4CE、CC2592、CC2651R3

Wired Interface

Several wired interfaces may be used for a variety of use cases. Power line communication over the solar power lines help reduce cabling cost and increase system reliability. Wired Interface includes RS-485 & RS-422 transceivers、General-purpose op amps、Line drivers, the corresponding products are SN65HVD1473、OPA2310、THS6222

Summary

Rapid Shutdown requirements are being adopted globally to protect firefighters while they work around solar PV equipment. The NEC requirement reduces the voltage to a safe level by using a series of devices (PVRSE) that make up a rapid shutdown system (PVRSS). Inverters, initiators, and rapid shutdown devices, such as MLPE or microinverters, are necessary components to comply with NEC regulations. Check out Tigo’s line of MLPE to learn more about rapid shutdown devices and our list of PVRSS certified inverters.

Previous: Electric power steering (EPS)