Electric and hybrid electric vehicles are gaining popularity as a sustainable alternative to gasoline or diesel-powered vehicles. One key component that determines the vehicles' operation, efficiency, and performance is the traction inverter.

In modern life inverters are a common electronic device utilized in a wide range of applications. Although they often go unnoticed, their significance is increasingly being recognized, and the term inverter or variations on it will become even more prevalent in media and marketing as the popularity of EVs continues to grow.

The term "traction" denotes the act of pulling or drawing something over a surface, thus a traction inverter is an inverter utilized to provide motion over a surface in coordination with an electric motor. Consequently, traction inverters can be found in all types of electric land vehicles, including trains, mining equipment, and increasingly, cars and trucks.

There are various names used to refer to these systems, such as variable frequency drives, motor drives, traction drives, variable speed drives, and traction inverters. If these systems work with electric motors that require AC power, they are considered inverters.

Products and reference designs of High-voltage traction inverter

High-voltage traction inverter

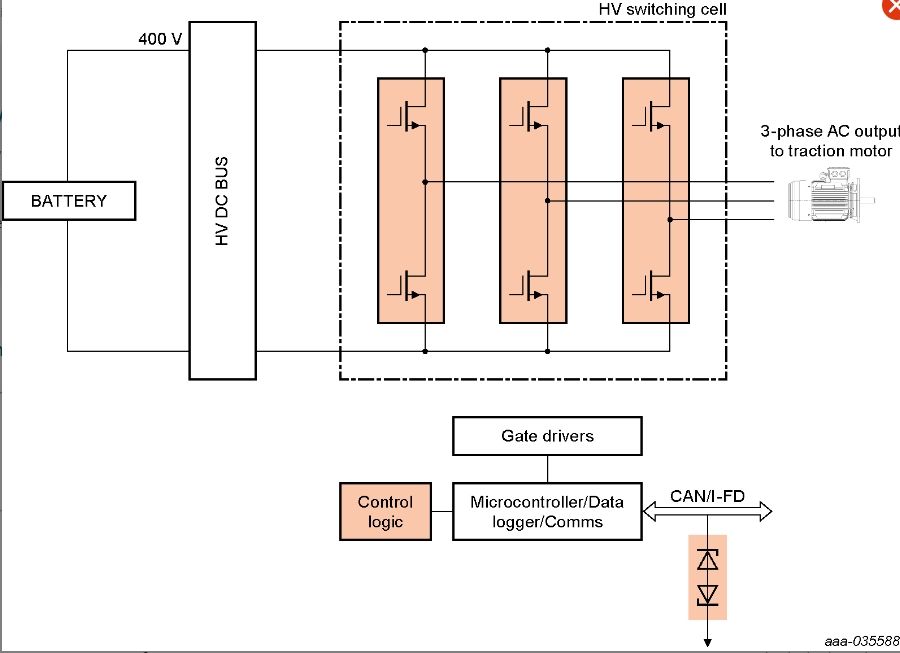

With both battery electric vehicles (BEV) or plug-in hybrid electric vehicles (PHEV), transferring the stored energy from the high-voltage (400 / 800 V) battery to the electric motors used to drive the wheels is the job of the high-voltage traction inverter. Traction inverters currently come in all shapes and sizes, ranging from 50 kW up to more than 500 kW with currents of several hundred amps. So safe and efficient DC to AC conversion is critical. In addition a small efficient traction inverter using GaN FETs can help eliminate the high-frequency whine associated with many battery powered vehicles.

Design considerations

●Dual electric motor architecture is more economical than one electric motor and a mechanical differential

●In premium BEVs trend is to have separate inverters – one for each axle or one for each electric motor

●To maximise range, inverters need to be extremely efficient yet at the same time be as small as possible, often with multiple dies per switch (4 – 8) and multiple switches per inverter cell

●Using GaN FETs eliminates the need for a separate body diode in the inverter switches.

Low voltage e-mode GaN FETs

Delivering optimum flexibility in power systems, Nexperia e-mode GaN FETs are ideal for high-power <200 V applications. Offering superior switching performance due very low QC and QOSS values. Enabling faster charging for e-mobility and wired / wireless changing systems as well as significant space and BOM savings in LiDAR and lower noise in Class D audio amplifiers.

Products

GAN3R2-100CBE:100 V, 3.2 mOhm Gallium Nitride (GaN) FET in a 3.5 mm x 2.13 mm Wafer Level Chip-Scale Package (WLCSP)

GAN7R0-150LBE:150 V, 7 mOhm Gallium Nitride (GaN) FET in a 2.2 mm x 3.2 mm x 0.774 mm Land Grid Array (LGA) package

GaN FETs: 650 V, CCPAK1212

Whether for low- or high-power conversion applications, Power Gallium Nitride FETs (GaN FETs) are increasingly making their way into mainstream markets. For a variety of 650 V and 150 V applications GaN FETs deliver the fastest transition / switching capability (highest dv/dt and di/dt), and best power efficiency. Additionally, Nexperia power GaN FETs bring enhanced power density through reduced conduction and switching losses.

Targeted at high-voltage / high-power applications, Nexperia cascode GaN FETs provide exceptionally high switching frequency capability for 650 V applications and the robust low on-resistance particularly suited for automotive electrification. For 650 V and ≤ 150 V industrial and consumer applications, Nexperia e-mode GaN FETs provide the balance between switching performance and robustness.

Products

GAN080-650EBE 650 V, 80 mOhm Gallium Nitride (GaN) FET in a DFN 8 mm x 8 mm package

GAN140-650EBE 650 V, 140 mOhm Gallium Nitride (GaN) FET in a DFN 8 mm x 8 mm package

GAN140-650FBE 650 V, 140 mOhm Gallium Nitride (GaN) FET in a DFN 5 mm x 6 mm package

Focus products

CCPAK GaN FETs (SMD)

As the innovators of copper-clip package technology, Nexperia brings 20 years experience of producing high-quality, highly robust SMD packaging to it’s GaN FET portfolio. Adopting proven technology, CCPAK gives industry-leading performance in a truly innovative package. Wire-bond free for optimized thermal and electrical performance, and simplified design of cascode configuration to eliminate the need for complicated drivers and controls.

Featured products

GAN039-650NTB

The GAN039-650NTB is a 650 V, 33 mΩ Gallium Nitride (GaN) FET in a CCPAK1212i inverted package. It is a normally-off device that combines Nexperia’s latest high-voltage GaN HEMT H2 technology and low-voltage silicon MOSFET technologies — offering superior reliability and performance.

GAN039-650NBB

The GAN039-650NBB is a 650 V, 33 mΩ Gallium Nitride (GaN) FET in a CCPAK1212 package. It is a normally-off device that combines Nexperia’s latest high-voltage GaN HEMT H2 technology and low-voltage silicon MOSFET technologies — offering superior reliability and performance.

TO-247 GaN FETs

Coupling Nexperia’s packaging expertise with the industry-standard TO-247 produces high quality, highly robust GaN FET products, satisfying the most demanding applications with unmatched reliability.

Featured products

GAN041-650WSB

The GAN041-650WSB is a 650 V, 35 mΩ Gallium Nitride (GaN) FET in a TO-247 package. It is a normally-off device that combines Nexperia’s latest high-voltage GaN HEMT H2 technology and low-voltage silicon MOSFET technologies — offering superior reliability and performance.

GAN063-650WSA

The GAN063-650WSA is a 650 V, 50 mΩ Gallium Nitride (GaN) FET. It is a normally-off device that combines Nexperia’s state-of-the-art high-voltage GaN HEMT and low-voltage silicon MOSFET technologies — offering superior reliability and performance.

650 V e-mode GaN FETs

Delivering optimum flexibility in power systems, Nexperia e-mode GaN FETs are ideal for low-power 650 V applications. Offering superior switching performance due very low QC and QOSS values, they bring improved efficiency to 650 V AC/DC and DC/AC power conversion. As well as bringing significant space and BOM savings in BLDC and micro servo motor drives or LED drivers.

650 V cascode GaN FETs

The very high electron mobility of GaN enables the creation of devices with low on-resistance and exceptionally high switching frequency capability. These advantages are vital in next-generation power systems, such as industry 4.0 and renewable energy applications. Nexperia cascode GaN FETs are the enabler in these applications offering high power density, high performance, and high switching frequency. This unique solution facilitates the ease of driving the devices using well-known Si MOSFET gate drivers. Additionally, they deliver unmatched high junction temperature (Tj [max] 175 °C), ease of design freedom and improved reliability of power systems.

LIN/CAN(FD)/FlexRay

Dedicated ESD protection devices to ensure safe operation

In-vehicle networks consists of multiple mircoprocessors communicating over different networks. LIN/CAN(FD)/FlexRay are highly reliable in-vehicle network protocols to handle the car's physically challenging environment. Nexperia offers dedicated ESD protection devices meeting emission, immunity and signal integrity requirements to ensure safe operation.

How Does a Traction Inverter Work?

In the context of electric vehicles, an inverter is an essential power electronic device that converts a direct current (DC) supply from the vehicle's batteries into an alternating current (AC) output. This AC output is then used to power the electric motor that drives the vehicle. However, inverters are not limited to just electric vehicles and can be designed to deliver power to the grid or anything else that requires AC power to operate.

In an AC motor, the current in each phase must alternate the direction of flow between positive and negative at the right time according to the motor shaft rotation and desired torque, similar to how a combustion engine requires the right amount of fuel and precise timing of the spark to operate. The faster the motor speed, the more frequent the alternation of current, just like the sparks in a combustion engine. This variable rate of changing current direction or frequency is precisely controlled by a traction inverter. Its primary function is to ensure the correct current is flowing in the motor phases at any instant by continuously monitoring the motor shaft angle and calculating the necessary current to produce the desired torque. The importance of the traction inverter in achieving optimal performance and efficiency in electric and hybrid vehicles cannot be overstated.

In electric and hybrid vehicles, the electric motor can also act as a generator during regenerative braking, converting the vehicle's kinetic energy into AC power. This is then converted back to DC power by the traction inverter, allowing the battery to be charged. It is worth noting that in electronics, a device that changes AC power to DC power is commonly referred to as a rectifier.

Previous: Electric power steering (EPS)

Next: Everything you need to know about the Onboard Charger for Electric Vehicles