What is a HVAC blower motor?

HVAC (Heating, Ventilation, and Air Conditioning) blower motors are the main components of air conditioning systems that send heated or cooled air into homes, offices, cars, etc.

Types of motor used in HVAC blower motors

The many different types of electronic motors can be broadly grouped into the following three categories based on their internal design and how they work.

●DC motors (powered by direct current)

●AC motors (powered by alternating current)

●Stepper motors (motors that rotate one step at a time in response to electrical pulses)

Two features that distinguish DC motors from the other two types are their high starting torque and ability to run at high speed. Typically, HVAC blower motors use AC or DC motors for their core. This page will focus on HVAC blower motors using a DC motor.

In order to understand the characteristics of a HVAC blower motor using a DC motor, we must first understand the characteristics of the DC motor itself.

DC motors can be divided into brushed and brushless DC motors

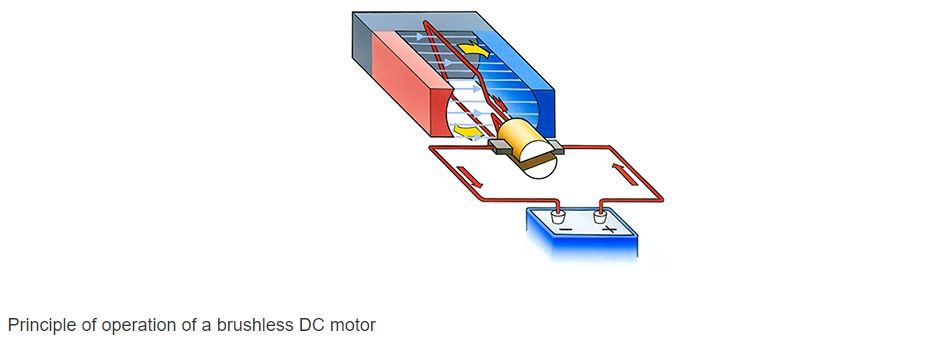

DC motors are divided into two categories depending upon whether they use brushes and commutators. DC motors that use brushes and commutators are called brushed DC motors, while those that use an electronic circuit instead are called brushless DC (BLDC) motors.

Differences between brushed and brushless DC motors

Principle of operation of a brushed DC motor

Brushed DC motors have their coil windings in the rotor. As the rotor rotates, the brush connections switch between commutators, thereby switching the flow of electrical current through each coil. By switching the direction of electrical current flow at appropriate times, the rotor can rotate continuously.

Advantages of HVAC blower motors that use a brushless DC motor

HVAC blower motors that use brushless DC motors have several advantages over those that use brushed DC motors. The three main advantages are as follows.

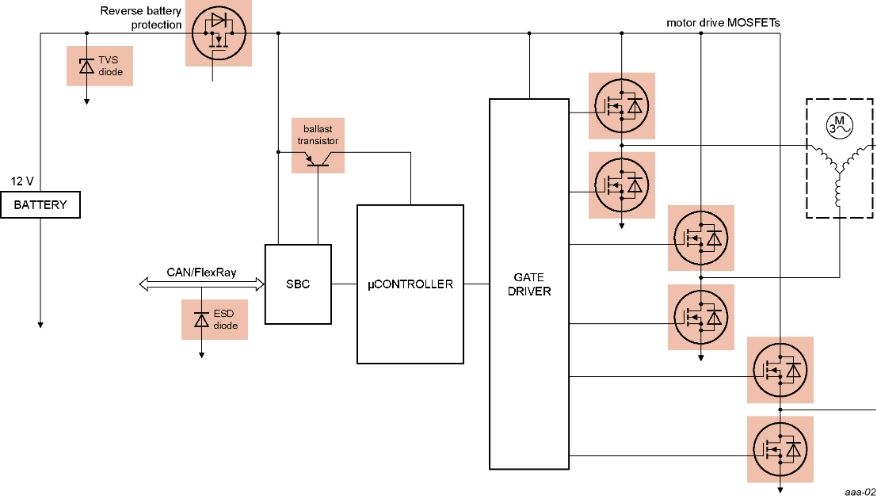

Automatic HVAC - BLDC blower motor Design considerations

Motor drive MOSFETs: 40 V, LFPAK

Automotive MOSFETs

The world's largest portfolio of AEC-Q101 qualified power MOSFETs

An in-depth understanding of automotive system requirements and focused technical capability enables Nexperia to provide power semiconductor solutions across a wide spectrum of applications. From driving a simple lamp to the sophisticated needs of power control in engine, body or chassis applications, Nexperia power semiconductors can provide the answer to many automotive system power problems.

Products

P-channel enhancement mode MOSFET in an LFPAK56 (Power SO8) Surface-Mounted Device (SMD) plastic package using Trench MOSFET technology.

This product has been designed and qualified to AEC-Q101 standard for use in high-performance automotive applications such as reverse battery protection.

Standard level N-channel enhancement mode Field-Effect Transistor (FET) in a plastic package using TrenchMOS technology. This product has been designed and qualified to the appropriate AEC standard for use in automotive critical applications.

Standard level N-channel MOSFET in a SOT404A package using TrenchMOS technology. This product has been designed and qualified to AEC Q101 standard for use in high performance automotive applications.

Schottky rectifiers: 100 V

Schottky diodes and rectifiers IF ≥ 1 A

Space and performance benefits for DC/DC converters

Our PMEG family of Schottky diodes and rectifiers with a forward current of 1 A and above are ideal as reverse polarity protection or freewheeling diodes in DC/DC converters. They provide space and performance benefits. Package options include automotive qualified copper clip-bond CFP packages as well as standard SMD and leadless DFN packages.

Products

Planar Schottky barrier double diode encapsulated in a SOT223 (SC73) Surface-Mounted Device (SMD) plastic package.

Planar Schottky barrier rectifier with an integrated guard ring for stress protection, encapsulated in a leadless ultra small SOD1608 (DFN1608D-2) Surface-Mounted Device (SMD) plastic package with visible and solderable side pads.

Trench Maximum Efficiency General Application (MEGA) Schottky barrier rectifier encapsulated in a CFP5 (SOD128) small and flat lead Surface-Mounted Device (SMD) plastic package.

ESD: CAN / LIN bus protection

LIN/CAN(FD)/FlexRay

Dedicated ESD protection devices to ensure safe operation

In-vehicle networks consists of multiple mircoprocessors communicating over different networks. LIN/CAN(FD)/FlexRay are highly reliable in-vehicle network protocols to handle the car's physically challenging environment. Nexperia offers dedicated ESD protection devices meeting emission, immunity and signal integrity requirements to ensure safe operation.

Products

ESD protection device in a small SOD323 (SC-76) Surface-Mounted Device (SMD) plastic package designed to protect automotive in-vehicle network bus lines from the damage caused by ElectroStatic Discharge (ESD) and other transients.

ESD protection device in a leadless ultra small DFN1006-2 (SOD882) Surface-Mounted Device (SMD) plastic package, designed to protect automotive in-vehicle network bus lines from the damage caused by ElectroStatic discharge (ESD) and other transients.

ESD: TVS, 24 / 40 W

Automotive Transient Voltage Suppressors (TVS)

For outstanding protection against transient over-voltage

Housed in very flat SOD128 or SOD123W packages, these TVS diodes save board space while guaranteeing industry-leading surge protection up to 600 W.

Overcome your problems with ASPINA’s HVAC blower motors

The key to blower motor development is to study the electric motor, fan, impeller, circuitry, and other components in detail to build up an accurate understanding of where performance losses occur. ASPINA draws on their expertise built up through many years of development, not only to optimize blowers or their motors to improve their performance, but also to make them smaller, lighter, have longer operating times.

Previous: Electric power steering (EPS)

Next: No results