Unleashing the power of your solar panels requires more than just sunlight. Inverters are essential components of every solar panel system. Think of it like this: solar panels capture energy from sunlight. Inverters harness that energy to create electricity compatible with your home.

More specifically, inverters convert the direct current energy (DC) your solar panels generate into alternating current (AC) electricity that your home appliances can use. These unsung heroes of solar panel systems come in all shapes and sizes and contribute to the overall efficiency of your system.

While traditional string inverters connect multiple panels to a single inverter, microinverters operate at the individual panel level. They can optimize the conversion process to boost your solar panel system’s efficiency. Let’s dive deeper into microinverters, their technology, and how they compare to other inverters.

What are microinverters and how do they work?

Microinverters convert the electricity from your solar panels into usable electricity. Unlike centralized string inverters, which are typically responsible for an entire solar panel system, microinverters are installed at the individual solar panel site. Most solar panel systems with microinverters include one microinverter on every panel, but it’s not uncommon for one microinverter to connect to a handful of panels.

Microinverters are classified as module-level power electronics (MLPE). Each microinverter operates at the panel site independently of the other inverters in the system. The individual nature of microinverters is advantageous for complicated installations or those with shading. Due to its centralization, traditional string inverter technology operates at the level of the lowest-performing panel. With microinverters, solar panels have their own inverters and will continue performing efficiently even if one panel isn't producing as much electricity as the others.

Pros of microinverters

Microinverters are an excellent investment for most solar shoppers, especially if you have a complex roof or one with partial shading. Microinverters operate at the panel level and don't require power optimizers for rapid shutdown compliance and optimization. If something is wrong with one microinverter, only the panel attached to it will shut down instead of the entire system. Diagnosing and fixing issues with microinverters is often quicker than with central string inverters.

Microinverters can easily grow with your solar panel system over the years. Let’s say your energy demands increase in the future. You can add more panels with microinverters instead of matching the power output of a central inverter with your new system size. Plus, most microinverters are warranted the same amount of time as the panels they're attached to (typically 25 years), so you can expect them to last longer.

Cons of microinverters

Microinverters are generally more expensive than string inverters. While you'll likely have better overall system performance with microinverters, it’s important to ensure that the long-term performance benefit outweighs the upfront cost. Microinverters are also located on your roof, making maintenance more difficult (and costly if your warranty doesn’t cover labor). Alternatively, string inverters typically sit more conveniently on the side of your house.

Clipping refers to power losses associated with microinverters and is an important consideration when shopping for a solar panel system. Often, the power output rating of your microinverter is lower than that of the panel itself. If your solar panel produces more electricity than its microinverter can convert at a given moment, clipping occurs, and your system can’t take advantage of the full power output of your solar panel.

When you should choose microinverters

Many homeowners choose microinverters. They're by far the most popular option on EnergySage. In part, this is due to their improved performance. Some installers also prefer them, meaning they include them in quotes more frequently.

Microinverters are a great choice if your roof has multiple planes facing different directions. They also make sense if your roof experiences shading throughout the day or has different angles to it. Let’s say you have some panels facing east and others facing south. In this case, microinverters optimize performance by isolating each panel's production issues.

However, if you have a single roof plane that's south-facing without shade, we recommend talking to our installer about different options. In this case, microinverters probably aren't worth the extra cost.

How do microinverters compare to other types of solar inverters?

Three common inverter options are microinverters, string inverters, and power optimizers.

Here's how microinverters compare:

String inverters vs. microinverters

●Wiring is the biggest difference between string and microinverters. Depending on the size of your solar panel system, you only need to use one or ●two string inverters to wire your panels. Microinverters often connect to just one panel.

●Given the minimal wiring requirements, string inverters are cheaper to install and maintain than microinverters. That said, the simplified wiring ●scheme can also make it more expensive to expand your solar system in the future. It also means that underperforming solar panels will affect the ●whole circuit rather than just its own output.

Power optimizers vs. microinverters

Unlike micro and string inverters, power optimizers don't immediately convert direct currents to alternate currents. Instead, they "condition" it and send it to a centralized inverter. These module-level power electronics (MLPEs) are similar to microinverters because they can monitor individual solar panel performance and allow flexibility when building a solar system.

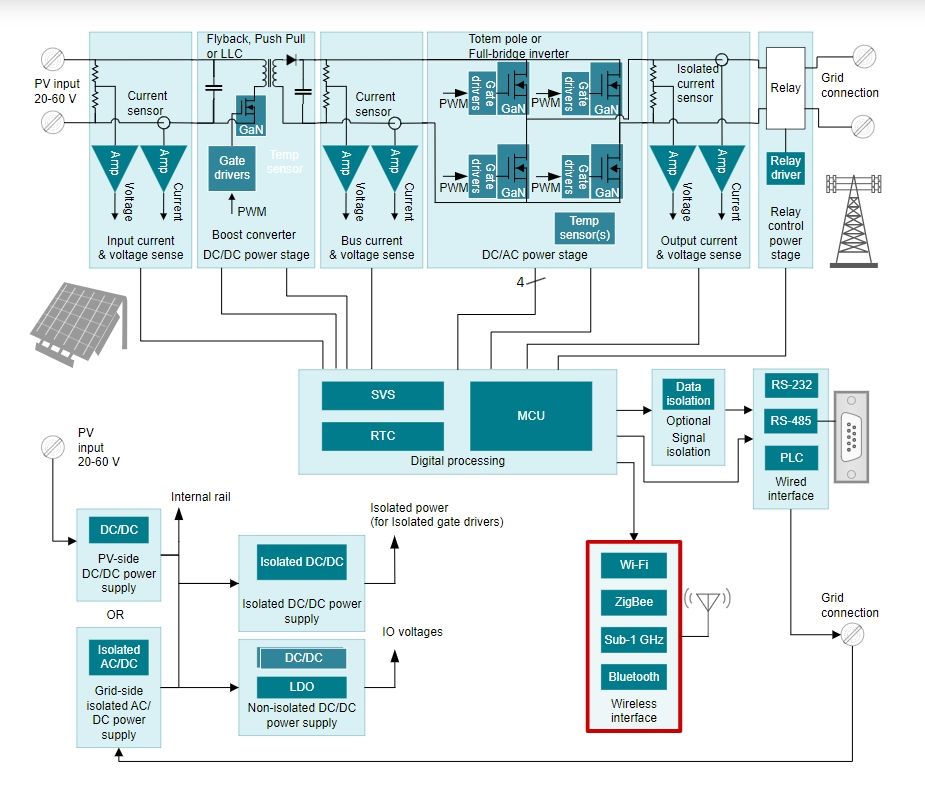

Products and reference designs of Micro inverter

Input current & voltage sense

Accurate and high speed sensory data of the various power busses in the solar inverter is required to effectively control the power electronics and ensure operational safety. Isolated sensory techniques are routinely used due to the high voltages involved. Input current & voltage sense includes General-purpose op amps、Analog current-sense amplifiers, the corresponding products are LM2904B、LM358B、INA296A

DC/DC power stage

The first power stage in an inverter is used to generate a stable internal DC voltage suitable for the operation of the inversion stage. With the low input voltage, a topology of boosting the low input voltage to hundreds of volts must be used. FETs must be sized appropriately, and matching dedicated gate drivers are used to ensure proper driving and operational efficiency. DC/DC power stage includes Half-bridge drivers、Gallium nitride (GaN) ICs、Low-side drivers、Analog temperature sensors, the corresponding products are UCC27289、LMG3522R050、UCC27517、TMP235

Bus current & voltage sense

Accurate and high speed sensory data of the various power busses in the solar inverter is required to effectively control the power electronics and ensure operational safety. Isolated sensory techniques are routinely used due to the high voltages involved. Bus current & voltage sense includes Hall-effect current sensors、General-purpose op amps、Precision op amps (Vos<1mV)、Analog current-sense amplifiers、Isolated amplifiers, the corresponding products are TMCS1126、TL082H、TLV2387、INA296B、AMC1311

DC/AC power stage

The regulated output of the DC/DC stage of the inverter feeds the actual inverter power stage. The switching characteristics and output filter of this stage lead to different implementations and selections of the gate driver. DC/AC power stage includes Isolated gate drivers、Half-bridge drivers、Gallium nitride (GaN) ICs、Analog temperature sensors、Digital temperature sensors, the corresponding products are UCC21330、UCC27201、LMG2100R044、TMP235、LMT01

Output current & voltage sense

Accurate and high speed sensory data of the various power busses in the solar inverter is required to effectively control the power electronics and ensure operational safety. Isolated sensory techniques are routinely used due to the high voltages involved. Output current & voltage sense includes Hall-effect current sensors、General-purpose op amps、Isolated amplifiers, the corresponding products are TMCS1126、OPA2994、AMC1311

Relay control power stage

The AC output of the string inverter must only be connected ot the grid when the sine waves have been properly aligned and tuned in order to not inject artifical reactive power. In addition, when grid voltages are not present, the inverter should not produce any output back onto the grid for safety reasons. To accomidate this, a normally open electromechanical relay is used to gate the AC output. Relay control power stage includes Solenoid drivers, the corresponding product is DRV110

Digital processing

Both main power stages in a solar inverter are controlled by a DSP. Using a DSP based solution power can be more efficiently captured from the solar array, and output harmonics can be much lower. Dedicated DSPs for the application will have sufficient MIPS or accelerators, as well as performance for a communications layer. Digital processing includes C2000 real-time microcontrollers、Supervisor & reset ICs, the corresponding products are TMS320F280039、TPS3828

Signal isolation

As working voltages continue to rise, so does the need for safety isolation. Any port that is human accessable on a piece of industrial equipment needs to meet certain safety ratings. In addition, communication between several pieces of equipment will need to be functionally isoalted to gurantee immunity against common mode transients. Signal isolation includes Digital isolators, the corresponding products are ISO6731、ISO7720

Wired interface

Several wired interfaces may be used for a variety of use cases. RS-485 to connect to external meters and building management systems, USB for configuration, and Ethernet to enable IP based communication are just the start. Each interface also needs to comply with IEC ratings, and may additionally require isolation for common mode rejection. Wired interface includes RS-485 & RS-422 transceivers、Ethernet PHYs、RS-232 transceivers、Isolated RS-485 transceivers, the corresponding products are SN65LBC180、DP83867E、TRS3243E、ISO3088

PV-side DC/DC power supply

The panel input voltage is nominally in the 20-60VDC range, and can be from very low voltages when there is low luminosity, or up to 100V in some newer modules. To support this, a wide input, HV, isolated DCDC converter is required to generate the internal DC voltages for the system. PV-side DC/DC power supply includes Buck converters (integrated switch), the corresponding products are LMR38020、LM76003

Grid-side isolated AC/DC power supply

For safety, redundancy, and simple operation reasons, solar inverters will typically be able to power themselves from either the solar array or the grid itself. Both of these supplies are used to generate an internal primary power rail, which other DC/DC converts can use. As such, both of the main converters needs to be capable to fully powering all of the electronics inside the system. Grid-side isolated AC/DC power supply includes Flyback controllers, the corresponding products are UCC28600、UCC28700、UCC28740

Isolated DC/DC power supply

In solar inverters the switching devices are isolated from the control domain. Isolated gate drivers are used for that. For this an isolated DC/DC supply is necessary, which converts typical <24 V to an isolated unipolar (i.e. 0 V ... 20 V) or bipolar supply (i.e. -5 V ...15 V). Isolated DC/DC power supply includes Isolated DC/DC converters & modules、PWM controllers、Transformer drivers, the corresponding products are UCC14141-Q1、LM5160A、UC2845、SN6501

Non-isolated DC/DC power supply

The internal electronics of a solar inverter require a number of separate voltage rails. MCUs and other digital controllers will typically run at 3.3V, some digital processors operate at however voltages like 1.2V, analog circuitry will need accurate low noise reference voltages, and power FETs and relays can require anywhere from 5-15V to turn on. Non-isolated DC/DC power supply includes Buck converters (integrated switch)、Linear & low-dropout (LDO) regulators, the corresponding products are TPS562203、TPS7A20

Wireless interface

Most modern residential solar inverters include a communication option to enable remote monitoring and control of the owner's system. In order to simplify installation, Wi-Fi is a popular option. Modern wireless SoC can enable quick development and deployment of compliant 802.11 stacks, and offer multiple paths to FCC certification. Wireless interface includes Sub-1 GHz wireless MCUs、Wi-Fi products、Low-power 2.4-GHz products, the corresponding products are , the corresponding products are CC1352P7、CC3200、CC2652P7

Previous: Electric power steering (EPS)